Oil & Gas

Although the individual processes are not as complicated as refinery processes, the dynamic and shutdown / startup issues are complex, especially in remote locations. A thorough understanding of these issues for startup and shutdown, manned and unmanned facilities, emergency control and overpressure protection, black startups, compressor train balancing and many other issues are provided by our team.

PROCESS is able to provide a number of standard services to upstream processors for both Onshore facilities as well as Offshore.

PROCESS can help with the following common issues in all areas of upstream processing.

Chemicals

PROCESS can provide preliminary design packages; mass and energy balances; complete process design packages with equipment specifications, capital and operating cost estimates; and any number of other process engineering services.

We have worked on a broad range of continuous chemical projects for many years, and that breadth allows us to rapidly respond to our client’s needs with quality engineering information. A few of the project categories completed many times by PROCESS have included:

-

Greenfield/Brownfield Plant Design

-

Continuous Process Scale-up

-

Capacity Evaluations

-

Process Debottlenecking

-

Capital Project Development Support (FEL-0, 1, 2, 3)

-

Process Troubleshooting

-

Chemical Recovery System Design

-

Process Simulation

-

Operations Evaluation

-

Utilities Systems Evaluation

-

Vent and Flare System Studies

-

Relief Valve Validation Sizing

-

Waste Treatment System Design

-

and more….

Petrochemicals

PROCESS can provide preliminary design packages; mass and energy balances; complete process design packages with equipment specifications, capital and operating cost estimates; and any number of other process engineering services.

We have worked on a broad range of continuous chemical projects for many years, and that breadth allows us to rapidly respond to our client’s needs with quality engineering information. A few of the project categories completed many times by PROCESS have included:

-

Capital Project Development Support (FEL-0, 1, 2, 3)

-

Pre-FEED (Front End Engineering Design) Studies, FEED Packages, and FEED Verification Services

-

Greenfield/Brownfield Plant Design

-

Continuous Process Scale-up

-

Capacity Evaluations

-

Process Debottlenecking

-

Process Troubleshooting

-

Chemical Recovery System Design

-

Process Simulation

-

Operations Evaluation

-

Utilities Systems Evaluation

-

Flare System Studies

-

Relief Valve Sizing Validation

-

Waste Treatment System Design

-

and more….

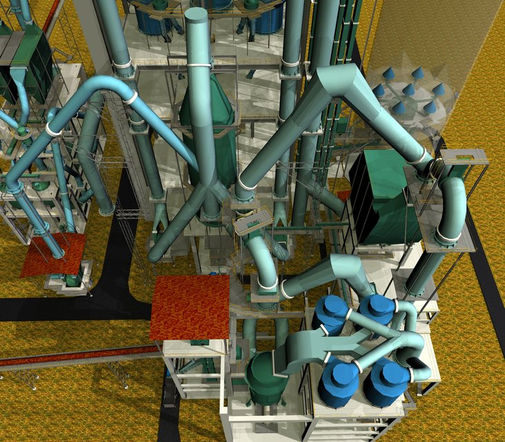

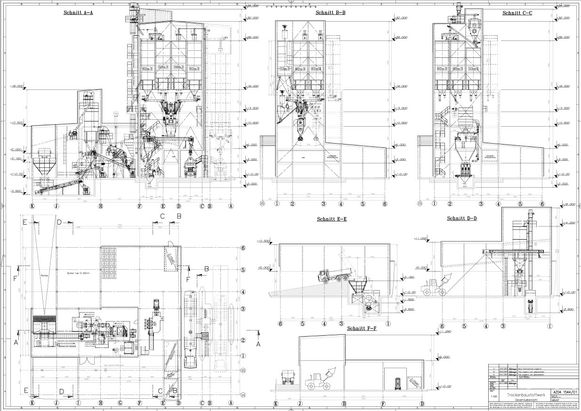

Bulk Handling And Processing Technologies

Vaestus GmbH is also in the field of bulk solids handling an internationally operating group of companies and a competent partner for different industries producing and processing bulk solids. We offer more than experience and Know How in the development and engineering of components for bulk solids handling with the core competences storing-, conveying-, metering-weighing, mixing, drying, separation, sizing, filtering technology as well as in the engineering and realization of complete, automatic bulk handling systems.

Food & Beverages

In the food and beverage industries, there is a growing need for a systematic approach to design complete processing systems. The demand for contamination-free consumables, as well as the customer-driven need for product freshness, have helped to stave off low cost import product competition. However, this situation is changing and large scale food manufacturers everywhere are facing the reality that they must either increase production efficiencies or lose market share to lower cost competition.

Oleochemistry

Vaestus GmbH is the best solution in serving the world’s oleochemical producers with advanced technologies. We design, engineer and study the most reliable, efficient and cost-effective oleochemical plants and process units for the production of fatty acids, glycerin, fatty alcohols, methyl esters and biodiesel. Our oleochemical portfolio is the outgrowth of decades of advanced design and engineering of hydrolytic oil splitting, distillation and fractionation as well as batch and continuous hydrogenation. You can rely on the expertise of our project teams to design, plan and execute your project within the shortest possible time. In addition to providing consistently high quality end products our plants are automated for ease of operation, require little maintenance and are very energy efficient.

Metals & Minerals

Most facilities include multiple unit operations to enrich and refine the valuable materials and then treat the tailings before disposal. Many common fundamental mass transport and separations technologies are incorporated, some chemical and some physical in nature (size reduction, floatation, magnetic separation, roasting, leaching, selective precipitation, ion exchange, solvent extraction). In addition to the core process, utilities optimization and well-engineered stream recycling can often make the difference between a profitable or unprofitable facility.

We design the process from the fundamentals up and utilize the expertise of our client and specialized equipment manufacturers as needed to help ensure the process we design will perform at an optimum level.

AT PROCESS, WE HAVE THE EXPERTISE TO SUPPORT OUR CLIENTS IN DEVELOPING INNOVATIVE METALLURGICAL PROCESSES FROM A CONCEPTUAL THEORETICAL PROCESS, THROUGH BENCH SCALE AND PILOT PLANT TESTING, TO THE ENGINEERING, CONSTRUCTION AND START-UP PHASES OF THE FACILITIES.

Water treatment

Water treatment is important to everyone. Whether you are responsible for the design and operation of an industrial complex that discharges to a surface water stream, or if you are in charge of a municipal water supply plant and want to help ensure your customers get what they expect, clean water is an asset we can’t live without.

While we are capable of municipal waste water plant designs, this is not where we choose to apply our skills. Our background as plant operations chemical engineers leads us to focus on other important types of water – Process Water and Industrial Wastewater.

Just as you recognize that the quality of your incoming chemicals can affect your product’s quality, the trace contaminants in your process water can affect your process and your products. Knowing what you are feeding into the process can help control what you are getting out. Additionally, proper process water conditioning can also help maintain operations efficiency by preventing unwanted fouling or corrosion issues leading to process equipment damage or unnecessary downtime for cleaning.

Most industrial wastewater treatment facilities are not seen as being a profitable part of the overall operation. Collecting, treating, and discharging is simply something that has to be done to keep a process plant in operation and in compliance with the regulations. So….how are you handling your residues? Are you losing product unnecessarily due to process inefficiencies? Is your back-end wastewater plant bottle-necking your main production line and limiting your productivity? Even worse, are you experiencing unwanted excursions in your wastewater treatment systems leading to noncompliance with environmental regulations? PROCESS can help minimize your wastewater treatment system problems and in turn help maximize your plant’s efficiency and profits.

Tank Farm Terminals

PROCESS possesses a staff of highly qualified process engineers willing and able to provide process design and process safety services to owners of terminal facilities. Storage, shipping, and receiving of gases or liquids is both safe and efficient if done correctly. Doing so involves a few basic issues: removing certain contaminates such as water, compressing/pumping/boosting the material to the next facility, appropriately storing/metering/blending materials, and receiving/shipping of materials by truck or rail. PROCESS is able to provide a number of key services to this market.