From Concept to Commercialization

At Vaestus we don't serve plain vanilla. With "imagineering" and a penchant for shifting the paradigm, we promise to generate some exciting and cost-effective options for you. That's because we're not afraid to put technology to the test. Vaestus’s engineers and technologists have broad experience in design and engineering plants and we offer all the services that our clients need to achieve success with their projects. As a design and engineering company, we can work on a turn-key basis or we can provide selected services that range from conceptual design to construction and start-up of the plant.

Our formula of engagement is simple. Give us your "wish list" and some running room, and we'll show you the Vaestus's difference. Be prepared for close and frequent communication. By the time your project is completed, we will know each other very well.

CONCEPTUAL ENGINEERING

FEASIBILITY STUDY

FRONT END ENGINEERING & DESIGN (FEED)

DETAILED ENGINEERING & DESIGN

PROCUREMENT

COMMISSIONING & START-UP

Conceptual Engineering

The early stages of front end project and process development are critical for the future success of projects involving new technologies and processes. The Conceptual Engineering and Feasibility Study phases provide a technical foundation for downstream engineering while evaluating the viability of a technology or process. Vaestus is uniquely positioned to help clients in these early stages to make their technology idea or process concept become a reality.

The Conceptual Engineering phase can generally be defined as a study phase where the initial technical concepts are further explored and defined and systematic documentation of the concepts are developed.

Process Scenario/Option Analysis

Experimentation

Kinetics, Equilibrium and Thermodynamics

Preliminary Process Simulation

High Level Heat and Material Balance (HMB)

High Level Process Flow Diagrams (PFDs)

Cost Engineering

Feasibility Study

The early stages of front end project and process development are critical for the future success of projects involving new technologies and processes. The Conceptual Engineering and Feasibility Study phases provide a technical foundation for downstream engineering while evaluating the viability of a technology or process. Vaestus GmbH is uniquely positioned to help clients in these early stages to make their technology idea or process concept become a reality.

The engineering feasibility study phase generally consists of a technical and economic analysis to investigate the probable outcomes of a project. The level of project definition and the amount of engineering is advanced beyond the conceptual engineering phase to increase the level of certainty of the analysis. This point in a project is an important decision gate to determine if the project should move forward.

Select preferred development options

Process simulation (Aspen Plus or Aspen Hysys)

Heat and Material Balance (HMB)

Reactor Selection

Separation Equipment Selection

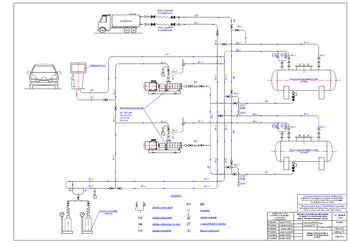

Process Flow Diagrams

Equipment Lists/Define and Size Major Equipment

Preliminary Piping and Instrumentation Diagrams (P&IDs)

Preliminary Plot Plan Development

Cost Engineering – AACE Class 4 capital estimates

Operating Cost Development

Front End Engineering & Design (FEED)

The feasibility study phase generally consists of a technical and economic analysis to investigate the probable outcomes of a project. The primary goal of Front End Engineering and Design (FEED) is to define the technical and project specific requirements for a system as to provide a clear scope and design basis for entering into the execution phases. The secondary goal of FEED is to develop a good project cost estimate that can be used for budget authorization and as a control baseline for execution phase work.

-

Process Simulation (Aspen Plus or Aspen HYSYS)

-

Heat and Material Balance (HMB)

-

Process Flow Diagrams

-

Applicable Codes & Standards

-

Piping and Instrumentation Diagrams

-

Utility Diagrams

-

Line Sizing/Hydraulics

-

Relief Valve Sizing/Flare System Hydraulics

-

Process Optimization

-

Value Engineering

-

Equipment Specifications

-

Exchanger Sizing (Aspen EDR)

-

Instrument Specification

-

Control Philosophy

-

Control System Definition and Specification

-

3D and 2D Modeling

-

Pipe Routing

-

Preliminary Discipline Engineering

-

Preliminary Bills of Materials/Material Take-offs

-

Cost Engineering – AACE Class 2 Capital Estimates

-

Project Schedule

Detailed Engineering & Design

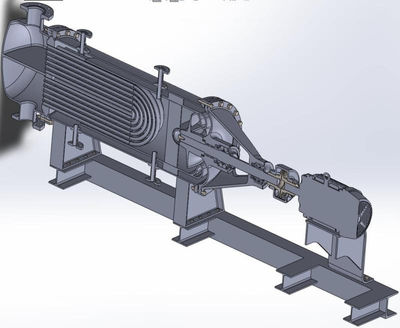

Mechanical

Vessel and Reactor Design

Exchanger Thermal Design (Aspen EDR)

Equipment Selection and Specification

Rotating Equipment Selection

Piping

2D and 3D System Modeling

Pipe Routing

Piping Isometrics

Pipe Stress Analysis

Structural

Structural Analysis (STAAD)

Structural Design

Foundation Requirements/Loading

Procurement

Procurement policies and procedures are of significant importance for implementing a project on schedule while retaining quality. We maintain an excellent relationship with our vendors who have been prequalified on a cost and benefit criteria. Comprehensive Requests for Quotations (RFQs) are prepared to ensure that there are no misunderstandings regarding the vendors' responses. Documents are carefully managed throughout the project and finally delivered to the client.

Vendor Identification, Qualification and Selection

Cost and Benefit Analysis

Quality Assurance

Vendor Document Management

Commissioning & Start-Up

Vaestus provides installation procedures and guidelines to assist the client in installing the modules. We always provide appropriate personnel for this activity. Vaestus has extensive experience in suggesting operational guidelines to ensure smooth start-ups while following the customer’s safety policies and procedures. When necessary, we participate in Site Acceptance Testing (SAT) to ensure that the system meets appropriate operational criteria.

Installation Assistance

Operating Guidelines

Maintenance Guidelines

Onsite Commissioning Assistance

Site Acceptance Test (SAT)