OIL & GAS

Although the individual processes are not as complicated as refinery processes, the dynamic and shutdown / startup issues are complex, especially in remote locations. A thorough understanding of these issues for startup and shutdown, manned and unmanned facilities, emergency control and overpressure protection, black startups, compressor train balancing and many other issues are provided by our team.

PROCESS is able to provide a number of standard services to upstream processors for both Onshore facilities as well as Offshore.

PROCESS can help with the following common issues in all areas of upstream processing.

UPSTREAM OIL AND GAS PROCESSING

UPSTREAM OIL AND GAS PROCESSING

Oil/Gas Separation

Flaring reduction/elimination

Hydrate prediction and prevention

Glycol dehydration

Desanding

Desalting

GAS PROCESSING

Slugcatcher specification

Hydrate prediction and prevention

Dehydration: MEG injection, silica gel, zeolite adsorption

Amine absorption

Dewpoint control unit

Mercury removal unit

Gas pipeline compression

Flow metering

Condensate stabilization

NGL PROCESSING AND LPG FRACTIONATION

Merox treatment

Benzene extraction

Condensate stabilization

iC5 rich extraction

PETROLEUM REFINING

PROCESS provides a wide range of engineering services to petroleum refineries. Our company has a great deal of refinery unit design, process safety, operations, and troubleshooting experience. After proving ourselves on smaller sized projects, many of our clients begin utilizing our services on a routine basis as an extension of their own in-house engineering team. From solving a vapor-locked pump problem to designing complete units, PROCESS can meet your needs.

OUR REFINING NICHE

PROCESS can provide preliminary design packages, Heat & Mass Balances, process and equipment design packages, and any number of front-end related services. This is true for most typical refinery processes, a few of which include:

-

Crude Units

-

Vacuum Distillation Units

-

Hydrotreating

-

Isomerization

-

Fluid Catalytic Cracking

-

Reforming

-

Coking

-

Visbreaking

We have worked on a broad base of refinery projects for many years, and that breadth allows us to rapidly respond to our clients’ needs with quality information and reliable front-end design packages. A few of the project types completed by PROCESS AND MECHANICAL have included:

-

Capacity Evaluations

-

Unit Debottlenecking

-

Fractionation Upgrade Design

-

Capital Project Development Support (FEL-0, 1, 2, 3)

-

Unit Simulation and Modeling

-

Energy Usage Improvements

-

Flare Header Studies

-

Relief Valve Sizing Validation

-

Balance of Process Design for New Technology Deployment

-

and more….

PROCESS is also able to provide a qualified 3rd party evaluation of refinery unit design packages and we are very adept at conducting unit capacity evaluations and revamp studies, utility evaluations, small to medium sized process designs, relief valve studies, and almost any refinery process safety related function.

PROCESS can also provide expert consulting services and bid evaluations on larger projects that may require additional resources. Examples of such larger projects would include reviewing the design package for a new Fluid Catalytic Cracker (FCC) unit or Hydrocracker.

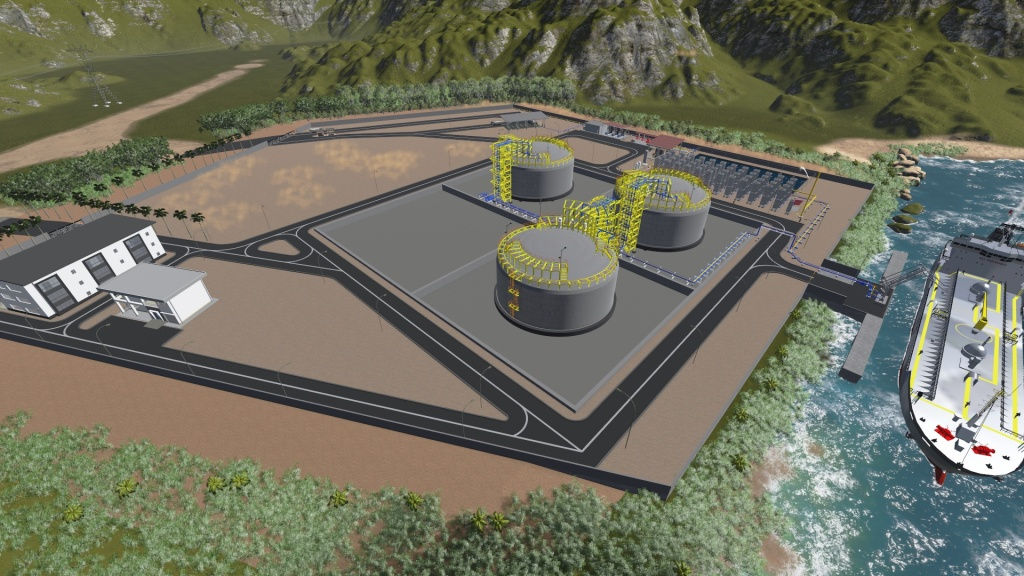

LNG LIQUEFACTION AND REGASIFICATION

WHAT WE OFFER

In addition to specialty areas of expertise, all of our standard services and deliverables apply equally as well to LNG facilities of all types. These include:

-

Conceptual process design development

-

Project Development Support (FEL-1, 2, 3)

-

Front End Engineering Design packages (FEED) and FEED verification

-

Preliminary and final process design packages

-

Technical process alternatives evaluations and feasibility studies

-

Design calculations and technical reporting

-

Process simulations and modeling

-

Mass and energy balances

-

Unit operation design/evaluation

-

Debottlenecking studies

-

Piping system hydraulics calculations

-

Process control scheme development

-

Control system startup, tuning, optimization

-

Creating Process Flow Diagrams (PFDs), Piping and Instrumentation Diagrams (P&IDs), and Process Control Diagrams (PCDs)

-

Process/equipment bid package preparation

-

Equipment specifications, and vendor technical proposal evaluation

-

Detail design and construction phase process oversight and support

-

Process evaluation, troubleshooting and optimization

-

Independent 3rd party design review

-

On-site process modification/construction oversight

-

Development of process documentation

LNG SYSTEMS EXPERIENCE

-

LNG facilities utilize a number of challenging compression and refrigeration systems. Dynamic simulation (dynamic compression evaluation programs) help ensure systems are protected and adequately designed for frequent start up and shut down under a variety of load conditions. Here are some examples of common LNG subsystems:

-

Process Systems

-

Pipelines

-

Condensate separation

-

Benzene removal

-

CO2 Absorption

-

Driers

-

Mercury absorption

-

Pre-cooling

-

Heavy hydrocarbon columns

-

Liquefaction

-

Sub-cooling

-

CO2 liquefaction/re-injection

-

LNG storage/loading

-

LPG fractionation/storage

-

Refrigerant makeup

-

Mono-ethylene Glycol (MEG)

-

Gas turbines and electrical (plus emergency power)

-

Compressed air