“Process design is the lifeblood of chemical engineering,” says Arberor Mita, President of Vaestus. “It’s all about using science and experience to develop and optimize the ‘best’ method to transform incoming feedstocks into higher value products.”

Vaestus’s principals have been involved in hundreds of projects for customers around the world. “Yes, we always start with proven chemical engineering fundamentals. But then we add experience, heuristics, intuition, computer simulation, and a ‘never-say-die’ attitude into the equation,” he adds. “It’s been a win-win formula that has enabled us to successfully work on assignments that many of our friends in the industry have shied away from.”

Block Flow Diagram Detailing

The Conceptual Engineering and Feasibility Study phases provide a technical foundation for downstream engineering while evaluating the viability of a technology or process. Vaestus is uniquely positioned to help clients in these early stages to make their technology idea or process concept become a reality. We work in close collaboration with the client to analyze different process scenarios and options for achieving project goals.

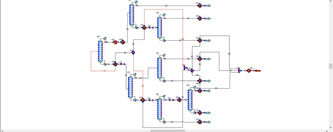

Over the last several decades, the technology of chemical processing has made extensive use of computer simulations to get a detailed and comprehensive understanding of processes. The key to these simulations is the quality of physical properties and attendant thermodynamics. Improvements of these factors now enable significant breakthroughs and increased confidence in using process simulations to generate meaningful data. An example of an Chemcad simulation is shown on the right.

Heat and Material Balance (HMB)

A major outcome of a simulation is to develop the Heat & Material Balances (HMB) wrapped around the process. The HMBs enable the design engineers to understand the thermal and mass transport values at various critical points in the process. An example of an HMB simulation output is shown on the left.

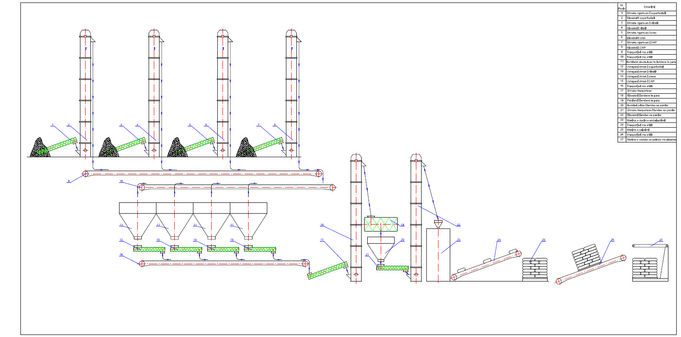

Process Flow Diagrams (PFDs) are a high level depiction of the process based upon the HMB to enable a better understanding of key aspects that are involved. PFDs are used to identify major unit operations and transformation points within the process. An example of a PFD is shown on the right.

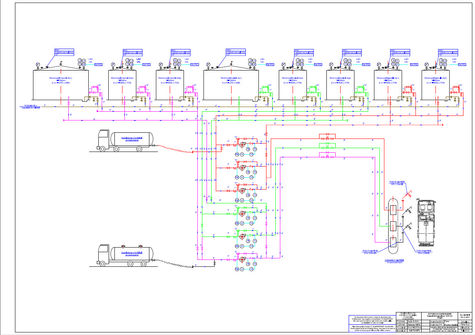

Piping and Instrumentation Diagrams (P&IDs) are an essential component of process design. P&IDs must show all the necessary piping and instrumentation that will be a part of the process. The P&IDs also establish a common protocol for communications between process engineers, piping engineers and instrumentation engineers. An example of a P&ID is shown on the left.

A typical process uses utilities such as water, air and electric power. Water may be used either in the process, or for cooling and/or production of steam. Air may also be used in the process or for instrument applications. Electric power of course is typically used at various points in the process and throughout the site.

It is always useful to develop diagrams that show the flow and utilization of each utility.

Vaestus uses Pipe flow expert software for conducting hydraulic calculations to determine the optimal line sizes for the gases and liquids flowing in the process.

In a typical process, there can be a number of options to proceed from start to finish. These may include use of alternate unit operations, operating conditions, and in some cases, an entirely different process design. Careful consideration should be devoted to analyzing the different combinations and permutations to approach a set of conditions that will minimize capital costs, or operating costs, or both. This protocol will typically help to optimize the overall process.

Value engineering is systematic approach to help improve the "value" of a given process. Value is usually defined as the ratio of function to cost. Value can be increased by either improving the function or reducing the cost. It is a primary tenet of value engineering that basic functions be preserved and not be compromised in this pursuit.

The objective of value engineering is as follows: if a client anticipates a research program to be of a short duration, the specifications of equipment and materials of construction may be optimized for that program. If the research program is of a longer duration wherein the plant not only provides process data but also long term product optimization, it may be necessary to utilize a different design basis and materials of construction.

A typical process includes a large number of major equipment items such as pumps, compressors, vessels, reactors, heat exchangers, mass transfer columns, etc. Each one of these pieces of equipment have to be very carefully and diligently specified to accommodate maximum operating conditions. Nozzle locations and sizes and materials of construction have to be appropriately specified.

Vaestus uses HTRI for conducting calculations for the design and specifications of heat transfer equipment. These items, commonly referred to as heat exchangers, include shell and tube type, exchangers, air cooled units, fired heaters, plate exchangers and plate fin exchangers. When needed, the program can also develop a tube sheet layout for specific applications.