Static Equipment Design

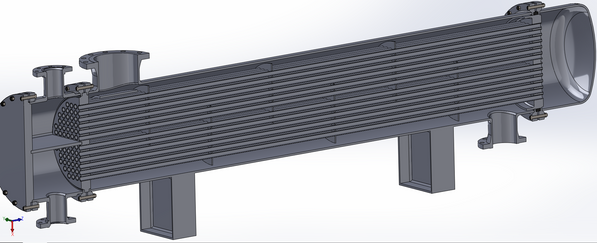

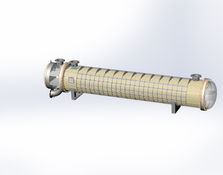

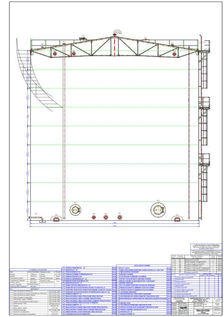

As per other type of equipment we offer full design service of all type of static equipment which the major ones include, reactors, towers (distillation absorption adsorption stripping extraction) heat exchangers (condensers, reboiler), liquid mixers, vessels, tanks, etc.

Vaestus static equipment engineering services comprises of the design and analysis of pressure vessels, storage tanks, heat exchangers, and boilers. Our proficient team of qualified engineers has the experience across industrial equipment and engineering companies of managing a wide range of projects for customers from petroleum refineries, chemical plants, petrochemical plants, pharmaceutical plants, food processing plants, wastewater plants, reactors, condenser, evaporators, and more.

We are the preferred choice for organizations from around the world for equipment design with high-quality performance, quick response time, and acute knowledge of international codes and standards like ASME Section VIII, PED, EN13445, AD 2000, API & TEMA for industrial equipment engineering services.

Mechanical/Structural Mechanical Engineering/ Piping Designer

Mechanical/Structural Mechanical Engineering/ Piping Designer (usually these disciplines are intertwined together) is involved in determining:

-

Detailed layout of the equipment

-

Selection and sizing of mechanical components for echampele bolt sealing couplings, plates, inernals, etc.

-

Material selection for each component of the equipment according to process requirements

-

Selections of operational and maintenance utilities like water requirements,oil requirements, etc.

-

Designing of non standard components like Shells, plates, pipe arrangements, distributors, accumulators etc.

-

Structural analysis of non standard components like Shells, plates, pipes, nozzles, seals, distributors, accumulators etc.

-

Preparation of drawings for manufacturing and assembling

-

Selection of drivers for moving equipment in the case of electric motor in collaboration with the electrical engineer (if applicable).

-

Nozzle sizing and specification

-

Piping layout and specification